TECHNICAL

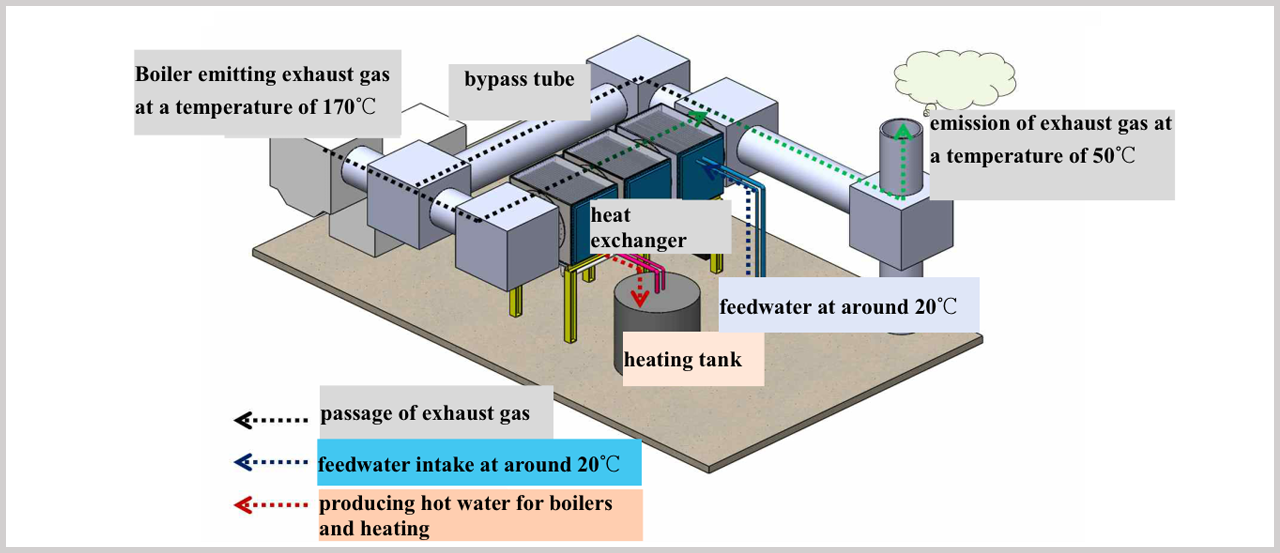

By using the low-temperature, high-efficiency condensable heat exchange system for the recovery of waste heat, high-temperature exhaust gas from heat-generating facilities (i.e. industrial boilers, incinerators, co-generation plant, thermal power plant, etc.) is converted to low-temperature exhaust gas, thereby preventing atmospheric warming. And then, heated water is reused for co-generation heating, water boilers and supply heating for buildings, as well as agriculture and aquaculture. SOx, dust, moisture etc. are condensed (condensed water) and reduced in the heat exchange system, resulting in reducing air pollutants, preventing white smoke as well as recovering and reusing waste energy.

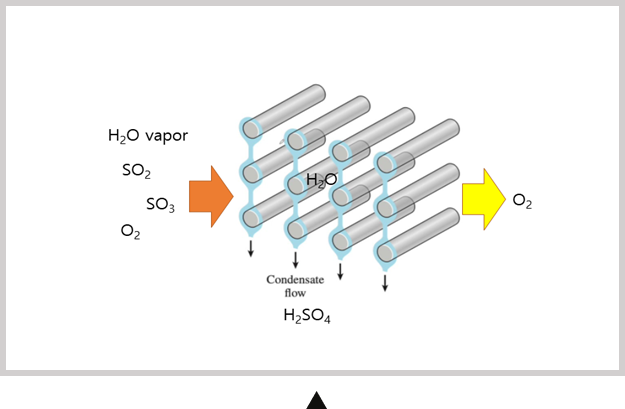

■ Reduction in the ratio of SOx

Delivery of Water-Condensed Sulfur Dioxide Gas Inside the Heat Exchange System

Sulfur present in exhaust gas reacts with oxygen to become sulfur dioxide gas, and then gets absorbed into moisture to become sulfuric acid.

Therefore, ratio of SOx in exhaust gas emissions can be reduced.

The reaction speed depends on reaction atmosphere in the heat exchange system.

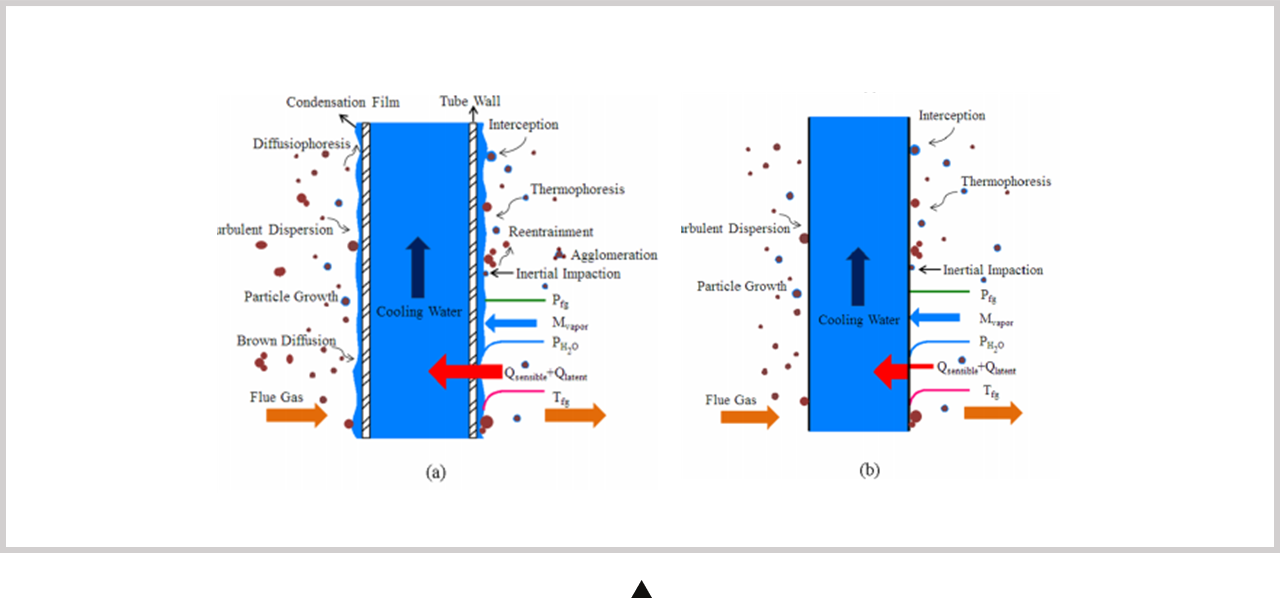

■ Significantly reduced fine dust content

The process of attaching and removing fine dust to the moisture condensing surface of the heat exchanger

Dust in exhaust gas is divided into various sizes depending on fuel and operating conditions.

The generated dust contained in the exhaust gas is attached to and removed from the moisture generated in the moisture condensing heat exchanger system, which significantly reduces the fine dust content

DAEMYUNG ESCO CO., LTD.

DAEMYUNG ESCO CO., LTD. / Address : 709, A, 170 Gwanggyojungang-ro, Yeongtong-gu, Suwon-si, Gyeonggi-do, Republic of Korea