Heat Generating Facilities Operator:

Industrial boilers, incinerators, co-generation, petrochemical, steel mills, thermal power plants etc.

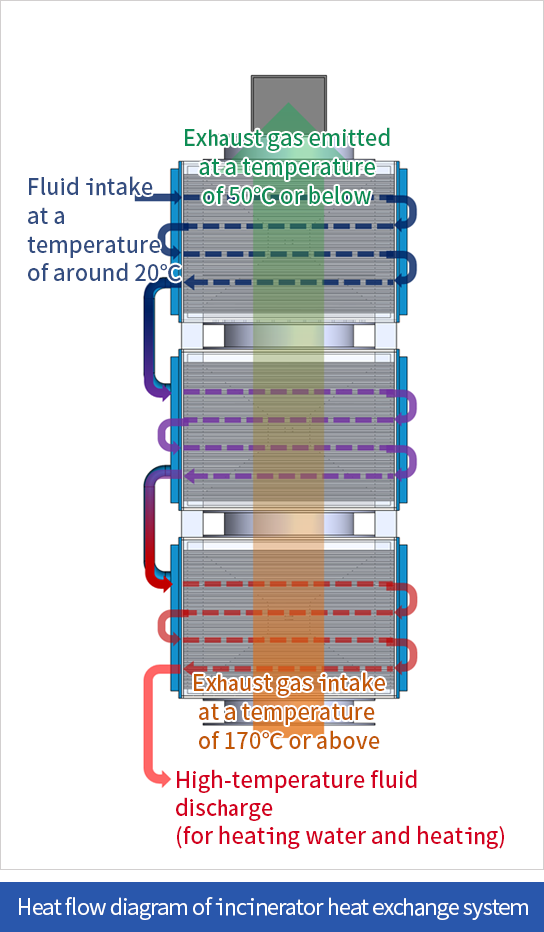

Recovery of waste heat from exhaust gas → improvement of energy efficiency;

Businesses using a large amount of hot water → used for heating water, supply of heating and makeup water.

Environmental Facilities Operators

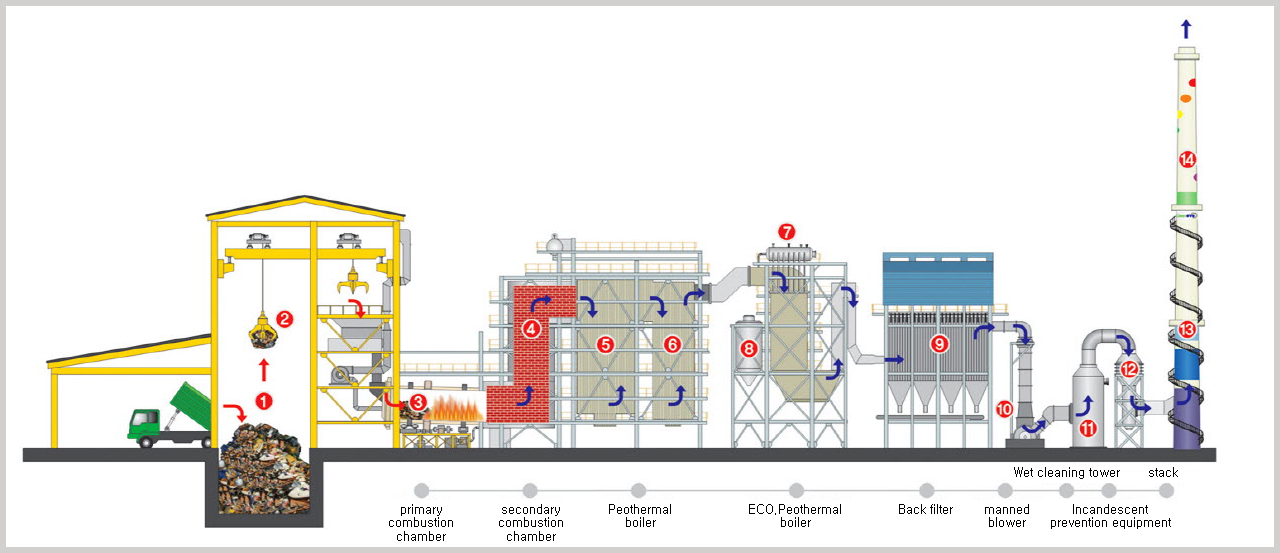

Design of desulfurization and dust collection facilities after installation of waste heat recovery heat exchange system

Reduce initial investment costs → Reduce commercial maintenance costs

Switching from high temperature to low temperature equipment → Securing economic feasibility

Securing economic feasibility

Post-stage facility design after installation of waste heat recovery heat exchange system

Reduce initial investment costs → Reduce commercial maintenance costs

Switching from high temperature to low temperature equipment → Securing economic feasibility

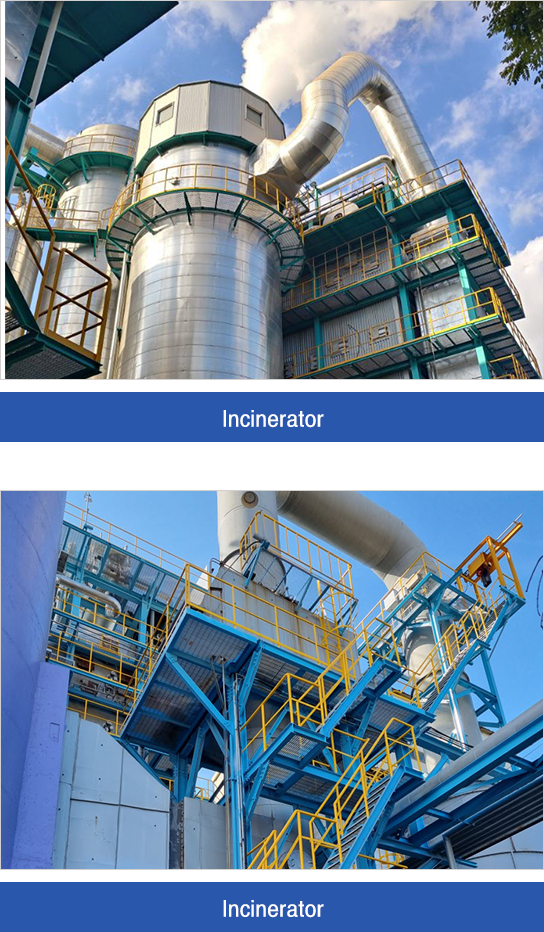

■ Incinerator

By installing a waste heat recovery heat exchange system, the high-temperature exhaust gas (200℃~250℃) generated in the process of incineration of incineration fuel (process by-products, household waste, designated waste, etc.) Because it is lowered to low temperature (below 50℃) An eco-friendly energy saving system that can reduce pollutants (Sox, moisture, dust, etc.) and white smoke caused by water vapor in exhaust gas, reduce pollution prevention facilities at the rear end, and reduce costs during commercial operation

DAEMYUNG ESCO CO., LTD.

DAEMYUNG ESCO CO., LTD. / Address : 709, A, 170 Gwanggyojungang-ro, Yeongtong-gu, Suwon-si, Gyeonggi-do, Republic of Korea